Laser cleaning and laser texturing in food industries

Food industries need cleaning methods to remove oxide films, grease and rust from surfaces that are used for baking, cooking and BBQing etc. Using chemicals and mechanical abrasive methods are not recommended because first of all they may damage the substrate and secondly the chemical methods may leave a residue that could be a potential health danger. In addition, to apply a chemical cleaning methods, the equipment needs to be taken apart such as in the case of mold in a press [Reference 1].

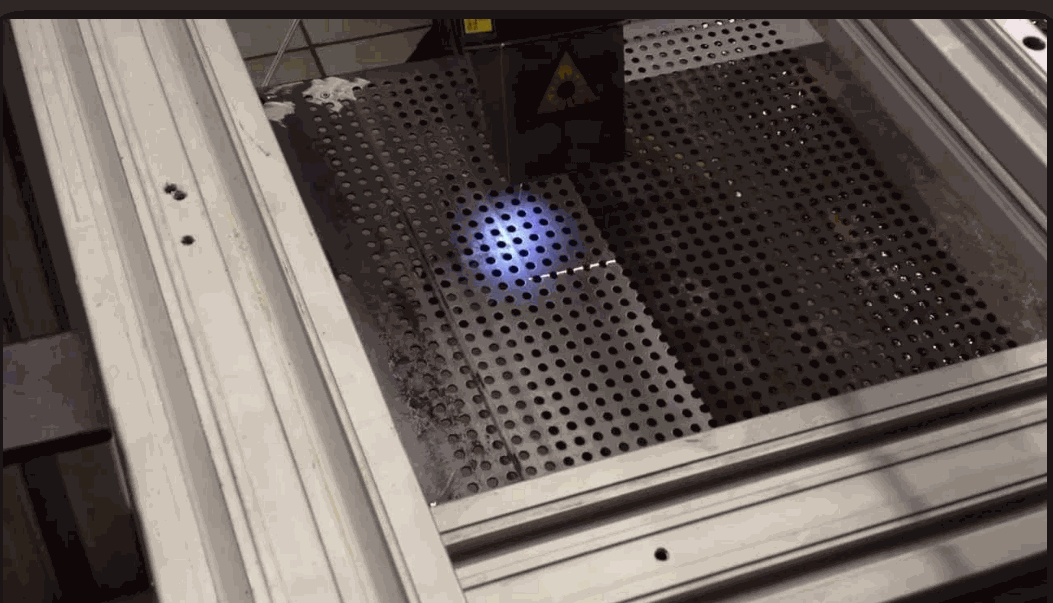

Laser cleaning is an alternative method that has many advantages over conventional abrasive or chemical methods. Q switched, nano-second pulsed lasers in near IR, are very effective in removing small particles which stick strongly to the surfaces [Reference 1]. Oxide and grease layers can be formed on surfaces that are used in the cleaning industry and for hygienic reasons, these surfaces need to be cleaned regularly. Laser cleaning has the advantage of being a non-contact method and can be used on delicate surfaces. Figure 1 shows a baking tray for which a contaminant layer is being removed using a laser cleaning device

Figure 1: Removal of contaminant layer from a baking tray using laser cleaning

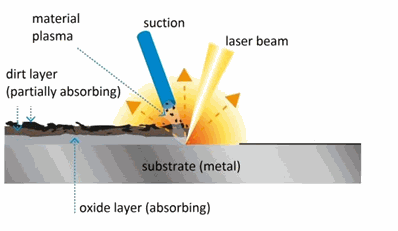

The gum residues, grease and rust films that are formed on surfaces used in the food industry are either absorbing or non-absorbing to the NIR beam. Oxide layers are normally absorbing and the first few pulses produce a photothermal ablation and the resulting plasma which creates micro-explosions removes the layer from the surface. When the metal substrate is exposed, subsequent pulses diffusely reflect from the metal substrate. If the top layer is made of grease, then it is totally transparent to the near IR beam and the transmitted beam reached the underlying oxide layer and produces micro-explosions which in turn remove the grease and the oxide layer itself. Figure 2 shows the laser cleaning process of an oxide layer on a metal substrate

Figure 2: Principle of laser cleaning [Reference 2]

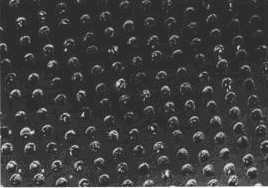

A different approach to keep surfaces clean and anti-bacterial in the food industry is the usage of laser texturing to create a water repellent surface topography [Reference 3]. Instead of laser cleaning the surfaces after they get dirty with bacteria, grease, rust and oxide films, why not create a surface topography which repels water, is antibacterial and doesn’t get dirty in the first place? Nature gives us an example of this type of surface in the form of water repellent properties in lotus leaves. The surface topography in lotus leaves has a periodic structure which traps pockets of air and therefore reduces the contact area between the liquid and the surface. Water remains in spherical droplets and the adhesion of bacteria on the surface is reduced. Figure 3 shows a picture of a periodic structure of lotus leaves and the spherical water droplets on its surface.

Continue reading

Laser-based manufacturing which uses high intensity beams with ultrashort pulses can be used to create surface topography similar to lotus leaves on plastic or metallic surfaces to produce water repellent and anti-bacterial properties. Bacteria can not stick to these surfaces because there is minimal contact between the liquid and the surface. Figure 4 shows an example of a laser textured surface which resembles a lotus leaf

Figure 4: Laser textured surface [Reference 4]

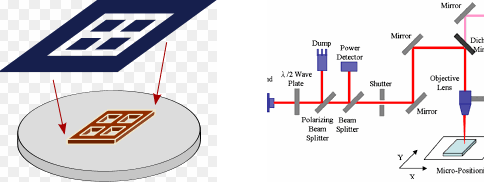

Laser Surface texturing (LST) to create surfaces such as shown in figure 4 is normally used using two different types of laser manufacturing methods [Reference 4]. In one method, called photolithography, pulsed excimer lasers with UV emission wavelengths and a UV sensitive mask are used to imprint a pattern on a metal or plastic surface. In another method, femto-second Nd:YAG lasers and an automated process is used to burn patterns on surface [Reference 5]. Femto-second lasers have minimal thermal effects and are suitable for micromachining. Figure 5 shows a mask for photolithography applications and also a setup for micromachining using a femto-second near IR laser [Reference 5]

Figure 5: Masks for photolithography applications (right) and femto-second laser machining (left)[Reference 5]

One application in the food industry where this laser texturing industry comes into use is in cases of big milk vessels in the dairy industry [Reference 3]. These containers need to be cleaned nearly every eight hours to prevent rapid growth of bacteria on their surface. As a result the production process needs to be stopped until the cleaning of vessels are done. Having the interior of these vessels laser textured would prevent the bacteria to deposit on the interior surface in the first place and would save time, money, and also increases productivity.

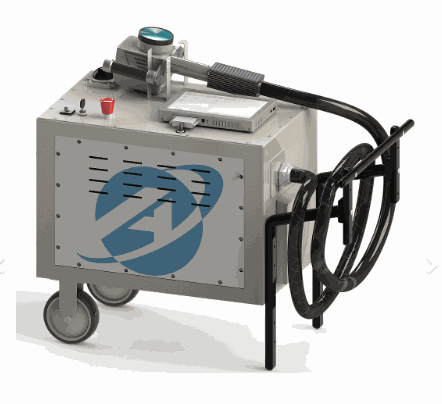

Allied scientific Pro (ASP) offers a number of laser cleaning systems which use high average power, NIR, nano-second pulsed fiber lasers and are very effective in cleaning metal surfaces. The food industry can take advantage of these laser cleaning systems to keep their surfaces free of contaminants. Figure 6 shows the laser cleaning systems offered by ASP.

Figure 6: LaserBlast-100 cleaning system

The LaserBlast-100 cleaning system has a galvo mechanism with optics which enables it to produce different beam shapes such as a linear, square, circular, elliptical, etc., which are suitable for different surface shapes.

Visit our dedicated Laser Cleaning Website to learn more

References:

1- S.Prandoni and P. Salvadeo, Industrial laser cleaning, Industrial laser solutions for manufacturing, 2002 (Online article).

2- Norton sandblasting equipment website.

3- Luca Romoli, Self-cleaning machinery for the food industry is getting closer, what’s new in food technology and manufacturing, 2017 (Online article).

4- Izhak Etsion, State of the art in laser surface texturing, Journal of tribology, 248, vol 27, 2005.

5- Chia-Lu Lee et.al, Using femto-second laser to fabricate highly precise interior three dimensional micro-structures in polymeric flow chip, biomicrofluidics 4(4):46502, 2010.