Introduction:

Before we start this technote which describes the role of lasers in welding, it is necessary to explain the different types of welding which will be referred to later on in the article. There are basically two types of welding which are called spot welding and seam welding. Spot welding only uses a single point electrode but in seam welding a rotating wheel electrode is used to produce a rolling resistance weld. Seam welding is continuous along a joint but spot welding is only done in one spot.

Several types of lasers have been used for laser welding and depending on the application, a selection needs to be made as to what type of laser has to be selected. Nd:YAG lasers are the most popular ones and have the largest installed base. They are routinely used for seam welding. They have moderate power levels (of the order of 20 W) for laser welding. Fiber lasers have more power (of the order of few hundred watts) and are also used for seam welding. Since the laser power for fiber laser can be increased to kilowatt levels, they can be used for applications of penetration depth of upto 0.25 inches. Diode lasers are also part of an established technology and they are used for laser welding of plastic for the tail lights of cars in the automotive industry [Ref 1]. Figure 1 shows these three types of lasers for welding.

Figure 1: From left to right, Nd:YAG laser, fiber laser and diode laser for welding applications [Ref 2, Ref 3, Ref 4]

Heating effect of laser:

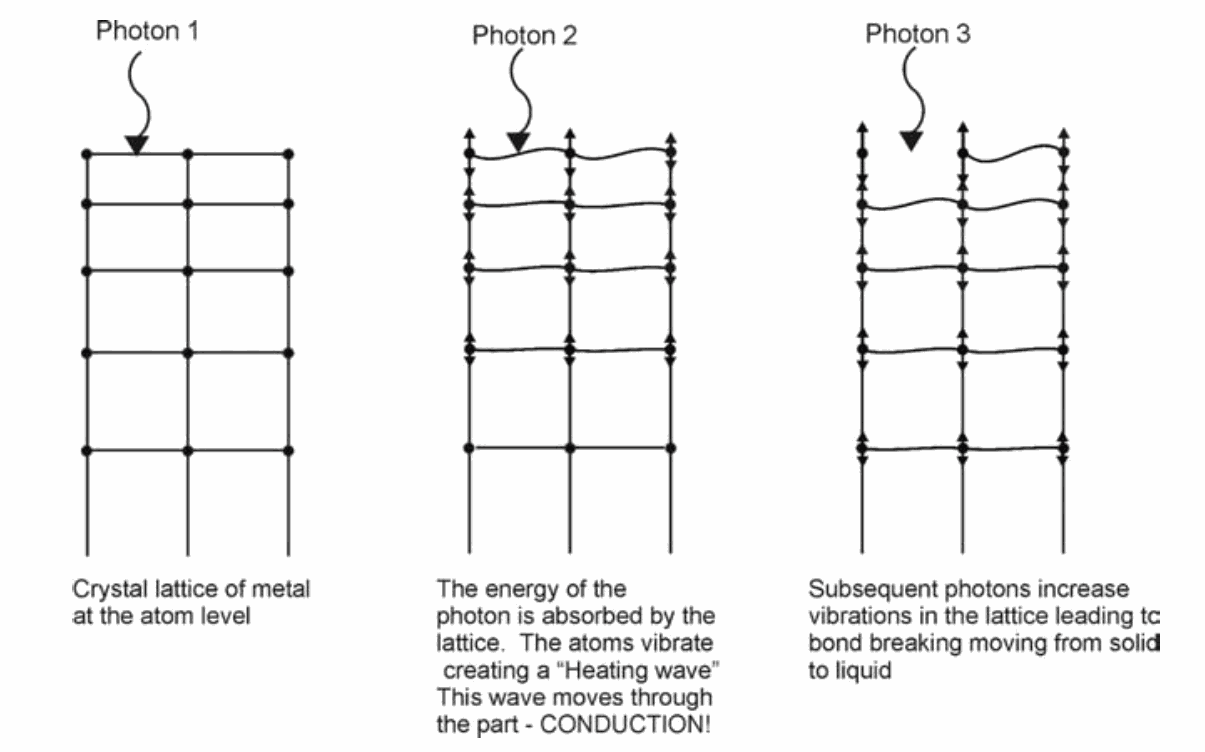

The laser has to heat up the material so it can melt it and then the welding can take place. Figure 2 shows the different effects that the laser can have on the lattice.

Figure 2: heating effect of the laser on the lattice [Ref 1]

Laser welding modes:

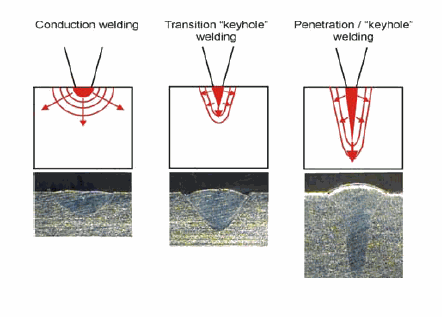

There are three different modes for laser welding which are called conduction welding, transition keyhole welding and penetration keyhole welding. Figure 3 below shows these three different modes.

A Punchy Headline

Figure 3: Different modes of laser welding [Ref 1]

The difference between these three modes is mainly the power of the laser used. The threshold irradiances are 0.5 MW/cm2, 1MW/cm2 and 1.5 MW/cm2 to achieve each of these modes.

Different parameters affecting the welding operation:

a) Pulsed and continuous wave operation

Spot welding typically uses pulsed operation however for seam welding the choice depends on the heat input and cycle time. Pulsed laser is used to minimize the heat but for faster applications, such as airbag initiators, CW is preferred.

b) Laser power stability

In order to have a proper weld, the power stability of the laser should be with +/- 3% other wise the weld will not be uniform.

c) Wavelength

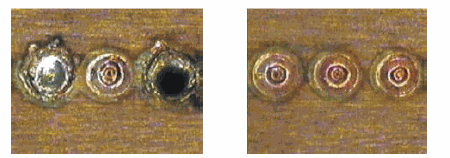

Some wavelengths are heavily reflected by some material such as 1 μm wavelength is heavily reflected by copper. The choice of wavelength is quite important in the selection of the laser. Figure 4 shows that the 1064 nm wavelength is not a good choice for welding copper because the quality of welding is pretty poor as is visible in the figure. On the other hand 532 nm is a better choice for welding copper.

Figure 4: Welding copper using 1064 nm laser (left) and 532 nm (right) [Ref 1]

d) Power ramping

In order to produce a good weld the power needs to be ramped up and down at the start and at the end of the laser weld. Otherwise the quality of the weld will be compromised. Figure 5 shows a proper laser weld where the power has been ramped down at the end so good quality of weld has been produced

Figure 5: Ramping down the laser at the end of the weld [Ref 1]

Time sharing and energy sharing:

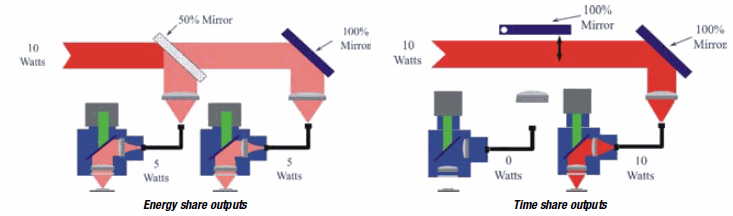

The laser can share its beam with many different outputs using beam splitters and this is called energy sharing. On the other hand it can also do time sharing when the outputs come on and off at different times. These two schemes are shown in figure 6.

Figure 6: Time sharing and energy sharing schemes [Ref 1]

Optimum pulsed Laser parameters:

When we mention pulsed lasers in this article, it is referring to both pulsed lasers of nanosecond pulse width and also to modulated CW lasers with μsec pulse width. The peak power of the laser, the pulse width and the pulse repetition rate are important parameters as far as laser welding is concerned. The importance of each of these parameters are described as follows:

● For both cases when the pulsed laser and modulated CW lasers are used, the peak power is an important parameter that needs to be optimized. Peak power is very important for laser welding and determines the depth of penetration

● Pulse width is more of a fine tuning parameter. It is used to control the width of the weld and its stability. It is also used to fine adjust the penetration depth of the weld. Increasing pulse width will increase the volume of the conduction zone and in turn a deeper weld is produced.

● The heating imparted by the laser into the material is controlled by the pulse repetition rate.

Optimum CW laser parameters:

The use of CW lasers for welding applications is mostly for speed and deeper penetration as opposed to pulsed lasers that are used more for finesse applications. CW lasers can be used for all modes of laser welding operations from conduction to key/hole penetration.

Advantages of laser welding over traditional welding methods:

Traditional arc welding methods such as TIG (Tungsten Inert Gas) and MIG (Metal Intert Gas) which use a shielding gas to create an inert atmosphere which surrounds the welding head, produce excellent finish and are good choices for welding small metal parts. However, these techniques require hand skills and also suffer from several disadvantages such as transfer of heat to surrounding areas which could cause deformation and use of consumables. Laser welding has a tightly focused beam and has the following advantages [Ref 5] over the arc methods:

● There is no contact between the laser head and the metal

● Scrap metal production is minimized

● Heat transfer to surrounding parts are minimum due to short pulses

● Miniature components can be welded precisely using the tightly focused laser beam (as small as thousandths of an inch)

● Due to the narrowness of the beam, the depth to width ratio of the weld is high and hence the weld strength is excellent.

● Deformation is minimized due to heat generated by short pulses.

Allied Scientific Pro has developed a fiber based laser welding system. The following link has more information about this fiber based laser welding system.

https://aspadmin-asensetek. odoo.com/ shop / category /lasers- laser-welding-64

References:

1- Laser welding by AMADA white paper.

2- https://www.assemblymag. com/ articles /90909-diode-lasers-for-

3- https://www.slideshare. net / vardaan2009/pulsed-nd-yag- laser-welding

4- https://www.youtube.com/ watch?v= xbiXeAORkeQ

5- The advantages of laser welding methods over traditional welding methods, online article, Laser Star Education, April 6, 2015.