Lead and zinc-based paint stripping using laser technology

This technote examines the removal of lead-based paint and zinc-based paint using laser technology. The two main references for the tech note are described below:

Lead-based paint: The reference from 1996 [Reference 1], examines the removal of a lead-based paints from wooden structures from bungalows in an air force base in Texas. The lead-based paint typically contains between 0.2 to 3.4 mg/cm2 of lead as was determined by the XRF measurement from various parts of the structure. The normal method of removing paint from these wooden structures is the chemical method. A CO2 laser-based paint stripper was used to remove the paint instead and the performance was compared as far as efficacy and cost to the chemical paint stripping. The Bungalows in the air force base are shown in figure 1

Figure 1: A typical bungalow in Kelly air force ba

Zinc-based paint: The reference from 2009, describes the removal of zinc-based paint from a water storage tank in San Bernardino airport in California near Los Angeles [Reference 2]. The paint layer on the water tank normally contains a Zinc primer and on top of that, there is a layer of polyurethane. The normal method of removing paint from this structure is sandblasting but in this case, once again a CO2 based laser cleaning system was utilized to remove the paint. The performance as far as the cost and the efficacy of operation is concerned is evaluated and compared with the sandblasting method. Figure 2 shows this water storage tank in California

Figure 2: Water storage tank with zinc based paint in California

Let us now compare the performance of laser cleaning system with the traditional method of paint removal for each structure.

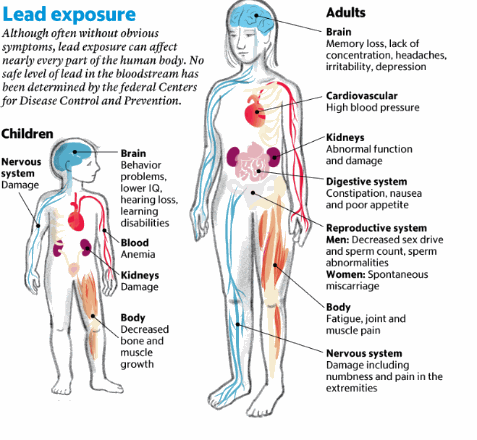

Laser paint stripping vs. chemical paint stripping for wooden structures with lead-based paint: In this case, the lead-based paint is typically removed using Methylene chloride (CH2Cl2) which is classified as a carcinogen and Toxic Air Contaminant in California. Aside from that one has to deal with the hazardous effects of lead particulate matter itself. These effects include nervous system, cardiovascular, brain, reproductive system damage, and many others as shown in Figure 3

Figure 3: Lead exposure damage to the body [Reference 3]

Instead of using a CO2 based laser system at 10.6 µm wavelength and 60-watt power, removes the lead-based paint with no need for hazardous chemicals. There is no need for environmental containment and worker protection. The waste from laser stripping consists of particles of paint itself which is directed towards a suction tube and passes first through a high-efficiency particle filter and then the gases pass through a car filter to remove the VOC’s. What is released to the atmosphere is simply hydrogen, oxygen, and nitrogen. Developing a laser system with a faster rep rate and more power makes the process more economical than the traditional paint stripping technique. Figure 3 shows the laser cleaning operation.

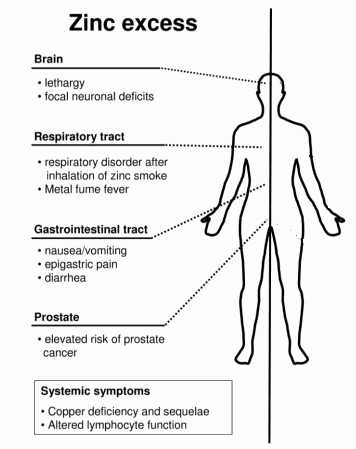

Laser paint stripping vs. sandblasting for water tanks with zinc-based paint: The traditional method of removing paint from water tanks as mentioned earlier is sandblasting. The blasting media needs to be contained because it carries particles of zins which is a hazardous material. The health effects of zinc on the body ranges from brain to respiratory tract to gastrointestinal tract to prostate as shown in figure 4

Figure 4: Hazardous effect of zinc on human body [Reference 4]

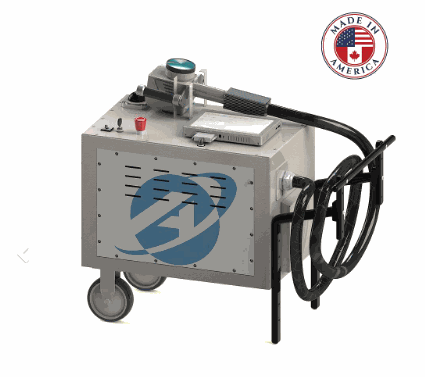

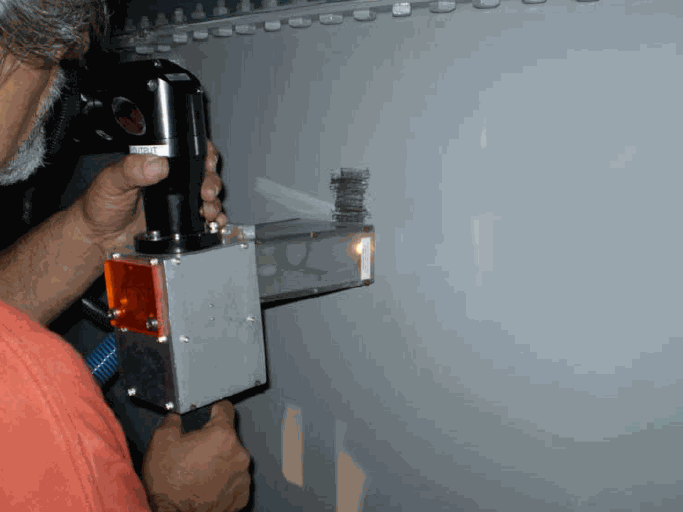

Using a 100 Watt portable handheld prototype the zinc-based paint was removed. The light is absorbed by paints or other contaminants and the high peak power results in a small explosion of the paint or contaminant which is vaporized. The light is not absorbed by the substrate and the laser can be tuned to remove coatings or contaminants one at a time. The paint or contaminant is drawn through a High-Efficiency Particulate Arrestor (HEPA) filtration system as it is blown from the surface, removing it from the airflow and the air is returned to the atmosphere. Figure 5 shows this system

Figure 5: laser system stripping the coating from water tank

This system is faster, cleaner and more economical to remove paint as compared to sand blasting.

Although CO2 laser have the advantage that the polymer paint absorbs heavily at their wavelength and has low absorption for the substrate metal (In this case Aluminum), they are not as flexible as near IR fiber optic lasers whose intensity could be carefully controlled and are fiber optic compatible so one can reach hard to reach places.

Allied Scientific Pro has developed such a paint stripping system as shown in figure 6. The link below the figure has more information about this system

A recent test using the laser blast 100 system removed leaded paint effectively from a test surface. Figure 7 shows laser blast 100 during the operation of leaded paint removal

Figure 7: LaserBlast cleaning system during the operation of leaded paint cleaning

Other optical pulse-based competing technology also exists which is based on surface discharge lamps [Reference 5]. However, surface discharge lamps produce a continuum of wavelengths including UV which require additional operator protection and use elliptical reflectors instead of fiber optic and laser scanner.

Visit our dedicated Laser Cleaning Website to learn more

References:

Demonstration of Lead-Based paint removal from a historic wood structure using laser technology. Report by U.S army construction engineering research laboratories, Kelly Air Force base. August 2, 1996.

A Portable Hand-Held Laser Stripping Device for Reducing VOC, Toxic and Particulate Emissions, Dr. Katy Wolf Institute for Research and Technical Assistance, December 2009.

https://www.sacbee.com/ news / local / health-and-medicine/ article71355742.html

The essential toxin, impact of zinc on human health. Laura Plum et.al, International journal of environmental research and public health, 7, 2010.

Lead paint removal with high-intensity light pulses, M. Grapperhaus, and R.B. Chaefer, Environ. Sci. Technol, 2006.