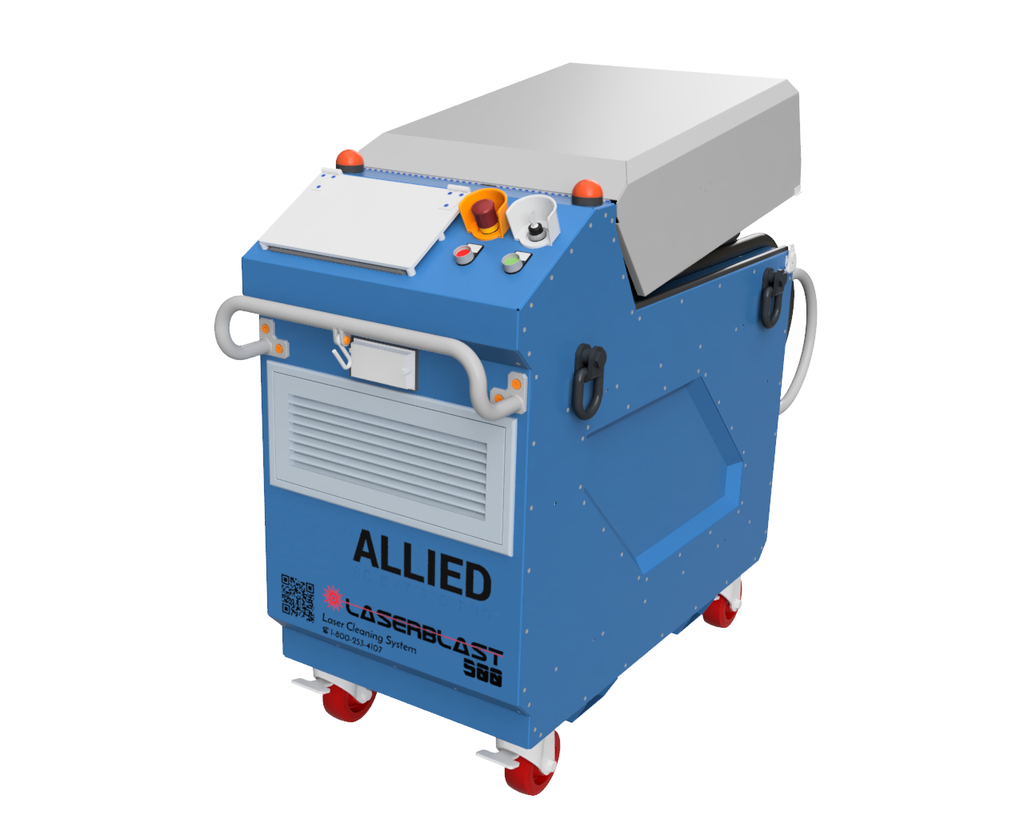

Allied Scientific Pro (ASP) has developed and manufactured a laser cleaning system to replace traditional blast media methods, sand, glass beads or dryice . Offering full control over a wide range of parameters allows for precise cleaning with the ability to retain patinas or industrial parts intact.

With a long legacy of expertise in laser nano and micromachining process, ASP is capable of offering a state of the art laser system to address the needs of the industrial applications. Our laser system is compact, robust and has a long lifetime with low or no maintenance for years. We are using the latest laser and scanner technology to offer high-quality performance and speed efficient cleaning without causing damage to the object.

ASP laser laboratory services can assist and by establishing optimal parameters for your application.

- 5 meters or more optical fiber delivery for remote access

- Short pulse with no thermal effect

- Long lifetime with the latest laser technology made in the USA

- Low cost of operation

- Water cooled which helps preserve the building

- One worker operation

Application

- Black steel A106 Grade B for pipeline ( see video section)

- Welding preparation of surfaces

- Rust and oxidation cleaning

- Mill Scale removal avoiding acid waste

- Surface smoothing varnish

- Surface texturing for paint adhesion

- Turbo engineer combustion chamber cleaning for power plant

- Radioactive surface cleaning for nuclear plant

- Part grease cleaning

- Coating removal

- Corrosion treatment

Key advantages:

- Reduce the total effective cost per sq/ft by 40% to 60% depending on the material

- Reduce labor cost: only 1 operator

- Avoid damaging the material base substrate

- No need for water, avoid water infiltration

- No need for chemical

- Reduce 90% of toxic waste disposal cost: solvent, media blasting, liquid waste

- Reduce risk of injury at work

- Environmental friendly

- Reduction in injury rate

- Reduce the cost of protective clothing

- Increase the lifetime of the substrate you are trying to conserve

- Zero consumables

- Zero preparation cost

- Easy on scheduling

Note: Effective cost includes; labor, preparation time, damage prevention, the power consumed, amortized equipment cost, consumable material costs, and residue disposition costs.

Key advantages of Laser cleaning of LaserBlast-500

Laser cleaning best in class!

| Cleaning Technique | Laser cleaning | Dry Ice | Sand | Glass Beads | Walnut Shells | Water | Steam | |

| Waste for Disposal | NO | NO | YES | YES | YES | YES | NO | |

| Abrasive | NO | NO | YES | YES | YES | NO | NO | |

| Toxic waste | NO | NO | YES | YES | YES | YES | NO | |

| Electrically Conductive | NO | NO | NO | NO | NO | YES | YES | |

| Comsumable needed | NO | YES | YES | YES | YES | YES | YES | |

| Other gear requiered | NO | YES | YES | YES | YES | NO | YES | |

| Preparation intensive | NO | NO | YES | YES | YES | YES | YES | |

| Environment friendly | YES | No(CO2) | NO | NO | NO | NO | NO | |

| Noisy | Very Low | Very High | Very High | Very High | High | High | Medium | |

| Vibration | NO | YES | YES | YES | YES | YES | Medium | |

| Dry process | YES | YES | YES | YES | YES | NO | NO | |

| Hazardous | Low | High | Very High | Very High | Very High | High | High | |

| Cause airborne particules | NO | YES | YES | YES | YES | YES | YES | |

| At-line-online cleaning | YES | NO | NO | NO | NO | YES | NO | |

| Work on hot or cold surface | YES | Sometime | YES | YES | YES | NO | YES | |

| Extra Nuzzel or tools to shape flow | NO | YES | YES | YES | YES | YES | YES | |

| Performance Comparison | Excellente | Great | OK | OK | Limited | OK | Poor |

| Parameter | Value | Unit |

| Laser Power Range | 25-500 | Watts |

| Laser Pulse Duration | 30-350 | Nanosecond |

| Laser Scan Size | 20-140 | Millimeter |

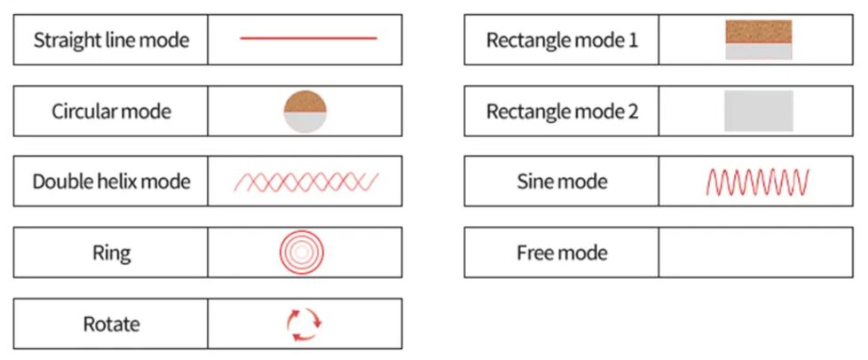

| Laser Scan Speed | 1000-15000 | mm/s |

| Electrical Power | 4.5 | Kilowatt |

| Electrical Voltage | 220 | Volts AC |

| Fiber Cable Length | 10 or 15 | Meters |

| Machine Weight | 180 | Kilograms |